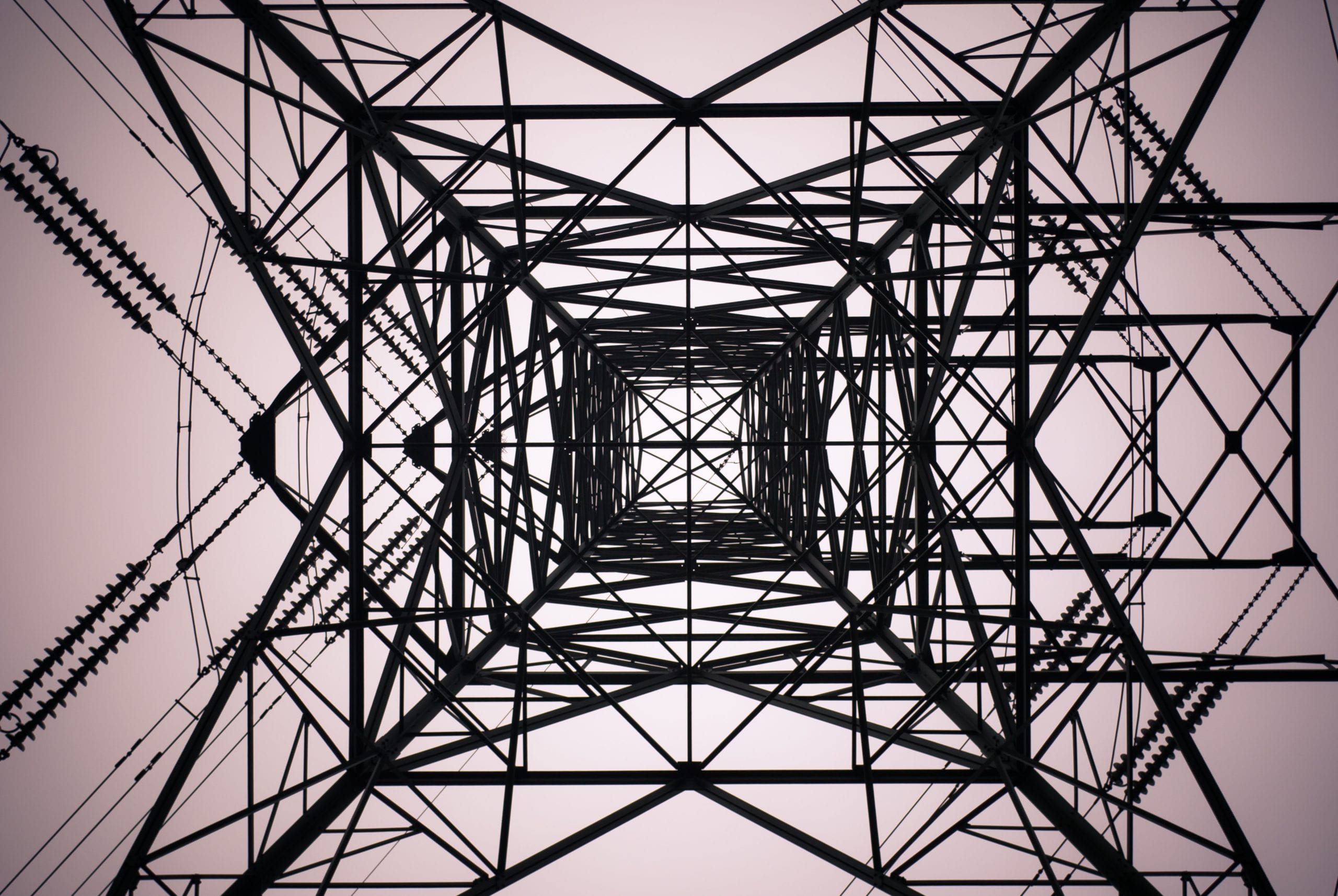

In the first part of this series, we outlined how electricity is generated and delivered to an electric vehicle (EV). To review, electricity is charged particles, generated by various fuel sources, moving at the speed of light. The electric grid transports electricity over power lines across often vast distances to its point of use. At any given moment, the amount of electricity on the grid must equal the amount of electricity requested by end-use consumers.

The act of fueling an EV is as simple as plugging in a cell phone or hairdryer. However, the business of EV charging and management is more complex.

The act of fueling an EV is as simple as plugging in a cell phone or hairdryer. However, the business of EV charging and management is more complex. Readers who want to transition their commercial fleets to battery electric vehicles face several total-cost-of-operation (TCO) considerations. Understanding the mechanics behind electricity pricing as well as which pricing factors can be controlled is a critical step towards optimizing, and minimizing, the long-term costs of fleet electrification.

How Electricity Pricing is Determined

The price a fleet owner pays for electricity is determined by several factors, including:

- Baseline and peak level of service required

- Time of day that electricity is consumed

- Site location

- Prices that generators charge utilities for their electricity

- Electric grid equipment cost

- Electric grid maintenance

- Extreme weather events

Accounting for these pricing factors makes the utility’s overall cost of distributing electricity to customers complex. For example, the per-kilowatt-hour price a utility pays to power generators can change by the minute and varies according to the fuel source (e.g., natural gas, nuclear, solar, or wind). Utilities factor these fluctuations in operating expenses into their suite of electricity prices which they then charge customers. Utilities will also calculate different per-kilowatt-prices for fixed rate structures than for time-of-use (TOU) structures. These prices and structures are updated only modestly several times every year and are subject to approval by a governing body.

Other electricity pricing elements that utilities commonly apply include fees for new equipment and for historical consumption patterns. On the equipment side, customers may be charged additional fees for meters installed on their site, or new equipment purchased to accommodate a significant service upgrade (such as for large-scale EV charging). On the demand side, customers may pay an extra fee if they require large quantities of power delivered at unusually fast rates. Geography can also affect a customer’s total electricity cost. For instance, a facility located in desert landscape with easy-to-maintain powerlines on a flat surface will have cheaper electricity costs than a facility located next to a wildfire-prone area in a mountainous region.

Rate Structures Can Shape the EV Transition

The cost to generate electricity varies over the course of a day, as does the amount of electricity demanded by a utility’s customer base. Utilities commonly offer customers two pricing packages, or rate structures, to account for these variations —a fixed rate and a time-of-use rate. An EV fleet’s rate structure is an essential factor of its TCO, and understanding the relationship between charging time and electricity cost can determine whether your project costs are net-positive or net-negative over the long term.

Under a fixed rate structure, a customer is charged a single price per kilowatt-hour regardless of their time of power consumption. By contrast, a TOU structure allows utilities to charge customers prices that are slightly more aligned with their actual operating costs at a given time of day. Most TOU structures apply a higher price per kilowatt-hour during designated peak periods, or times when the demand for power is high. At these times, per the principle that demand drives cost, utilities pay a higher price to buy the power that they need to meet customer demand. The price per kilowatt-hour then drops during off-peak periods, when the utility expects to purchase smaller amounts of cheaper power for fewer people. These periods may also coincide with, for instance, times when excessive solar is available on sunny afternoons.

The predictable nature of rate structures means that fleets can plan accordingly and select the site layouts, charging hardware, and time frames that optimize their operating costs.

Some utilities offer lower, EV-specific rate structures to encourage EV adoption. The predictable nature of rate structures, particularly TOU rate structures, means that fleets can plan accordingly and select the site layouts, charging hardware, and time frames that optimize their operating costs.

Service providers can help fleets transitioning to EV’s to understand the process and achieve reliable operations and a low cost of fuel. A fleet operator can elect from an array of benefits available as a service. Some firms handle design and construction of charging infrastructure on one end of the spectrum. On the other end are turn-key project solutions that cut cost and time for capital planning, energy management, and electricity billing.

We share several lessons for fleets to plan for this transition, select the right partners, and ensure a smooth transition here:

Addressing Charging Challenges from a Rate Structure Perspective

The most common obstacles to EV charging depot development are related to site readiness, project cost, and operational compatibility. When confronted with these obstacles, a rate structure may not seem like the obvious tool to develop a solution. This section outlines charging strategies that can provide cost-effective direction to a charging program.

Challenge: Site upgrades to accommodate EVs are costly and time-intensive.

Many fleets may find that their depot’s electric infrastructure is undersized relative to the electricity supply their EV fleet will require. If their transition strategy involves a gradual roll-over from diesel to electric, then the construction and permitting requirements may appear too daunting to repeat at each new phase. Fleets may also be reluctant to invest heavily in a single design if they believe that the technology and options will change over their project’s lifecycle.

Solution: Design and permit with a nod to the future.

Although designing an EV charging depot and program is best done in an iterative process, taking frequent feedback into account, fleets can control total project costs by minimizing their engineering and permitting requirements. Designing and permitting for the full project scope upfront, instead of at each stage, allows fleets to build in phases under a single, maximally sized permit. Aspects like sizing electrical service panels for your largest forecasted demand, and laying future-oriented conduit during the initial trenching, avoids the time and expense of re-permitting to upgrade this equipment at each new phase of your EV transition.

Designing and permitting for the full project scope upfront, instead of at each stage, allows fleets to build in phases under a single, maximally sized permit.

Challenge: Equipment and long-term electricity costs are not competitive with diesel.

Fleets understandably prefer a pricing solution that is as similar to fueling with diesel as possible, and accordingly may design their EV program around the fastest charging solution available. This assumption often leads to a prohibitively expensive TCO. The additional costs often come from demand charges, rate structures, and possibly new equipment costs. It may seem impossible to decipher where the costs can be cut.

Solution: Plan for slower and longer charging sessions.

Slower and longer charging can mitigate charging and equipment costs while improving equipment lifetime. Fast charging equipment requires a higher level of electricity service from your utility, driving up equipment costs as well as your per kilowatt-hour price. Because these chargers deliver large amounts of power quickly, their utilization is often low. Planning a charging schedule to use cheaper, lower-powered chargers steadily for long periods of time may reduce your equipment costs and limit your total power demand, which translates to lower demand charges and possibly even a lower-priced tier of your utility’s rate structure.

Slower and longer charging can mitigate charging and equipment costs while improving equipment lifetime.

Solution: Plan around TOU energy prices.

Electricity is often cheaper late at night and early in the morning although exact time frames for higher or lower pricing strategies vary by utility. A fleet manager can take advantage of these electricity pricing variations by aligning actual vehicle needs in terms of mileage and dwell time with TOU rates to avoid on-peak charging. Charging vehicles at higher power levels could be reserved for off-peak periods. When planning around your rate structure, it is important to know whether your utility sets a demand charge according to a customer’s monthly or annual peak demand, as this can inform your pricing forecast and power management plan.

Solution: Maximize charger utilization.

Designing your charging plan for maximum use will lead to a better return on investment for design, permitting, and construction costs. Using a given charging system for relatively few hours a day is not ideal as construction costs on a per-charger basis can be high. In addition to planning for overnight/off-duty charging, consider whether your equipment can be shared by multiple fleet vehicles, employees or the public during the daytime, possibly for a fee in line with market rates. This may require some additional networking and security investments.

Designing your charging plan for maximum use will lead to a better return on investment for design, permitting, and construction costs.

The Value of Feedback

Feedback from drivers and depot staff on EV performance and charging programs is valuable for building driver acceptance and implementing EVs in your fleet. Feedback can take place informally during preparatory meetings or more formally through surveys and scheduled vehicle reviews. Reviewing vehicle daily miles travelled and fuel diagnostics can be helpful in the early phases to make EV implementation as useful as possible. The frequency and method by which your fleet pursues this feedback will vary depending on your company’s needs but can be extremely useful.

Overall, the return on your EV investment will closely follow your project’s site design, timeline, and charging program. Aggregating EV fleet experience and learning from successful electric charging strategies is crucial as we deploy, implement, and begin to scale electric fleets.