The commercial trucking industry is at an inflection point when it comes to demand for electrification and sustainability.

The recent rise in e-commerce and middle- and last-mile delivery, concurrent with multiple state-level zero-emission mandates, has accelerated the commercial EV market while driving significant investment in electric chassis for end-user fleets.

Demand for moving trucks, daily rentals and delivery box trucks has exploded as has the demand for EV-focused fleets. Grocery suppliers and home delivery of fresh groceries are contributing to demand in the refrigerated category. And, with soaring fuel prices, drivers and fleets are feeling the pinch and exploring electric alternatives. As this dramatic transformation takes place, Morgan Truck Body is focusing on innovative designs that provide electrified solutions to support the transition to zero-emission transportation.

Recent surging demand for electrification has been a catalyst for innovation.

Meeting the Needs of Fleet Owners

Fleet owners seek energy-efficient solutions that offset the weight added by batteries without losing cargo capacity and delivery range. Driver education is also paramount as the industry deals with elevated labor shortages and the associated burden placed on drivers. And for those already making the transition to electrification, the entire industry has been dealing with a tight supply chain over the last two years.

Morgan Truck Body is positioned to meet this growing demand and has been collaborating with chassis OEMs to deliver zero-emission products that reduce the carbon footprint of commercial truck fleets. Our 14 manufacturing locations and 8 company-owned service centers throughout the U.S. and Canada are being upfitted with charging infrastructure, new tools, training, and processes.

Three Innovative Tech Solutions

We first began working toward electrification and alternative fuel solutions in the 1990s, and recent surging demand for electrification has been a catalyst for innovation. The company has been investing heavily in manufacturing capacity for mounting and integrating commercial truck bodies to electrified chassis. Last month, Morgan introduced two innovative concept bodies designed with composite materials that reduce weight without compromising strength. We will showcase our vision of the future at ACT Expo in May, and throughout the year, with EV concept bodies that are the culmination of extensive collaboration with technology partners to achieve the most versatile, advanced solutions.

The advanced bodies incorporate innovative technologies and features in three key areas:

Weight Reduction – Engineering to offset the added weight associated with EV chassis, using advanced composite wall panels and lighter materials for the frame, subframe and accessories to address payload capacity concerns, all without compromising structural integrity.

Image: Morgan Truck Body

Improved Aerodynamics – The addition of cab-mounted fairing, side skirting and wheel covers extends operating range by reducing aerodynamic drag.

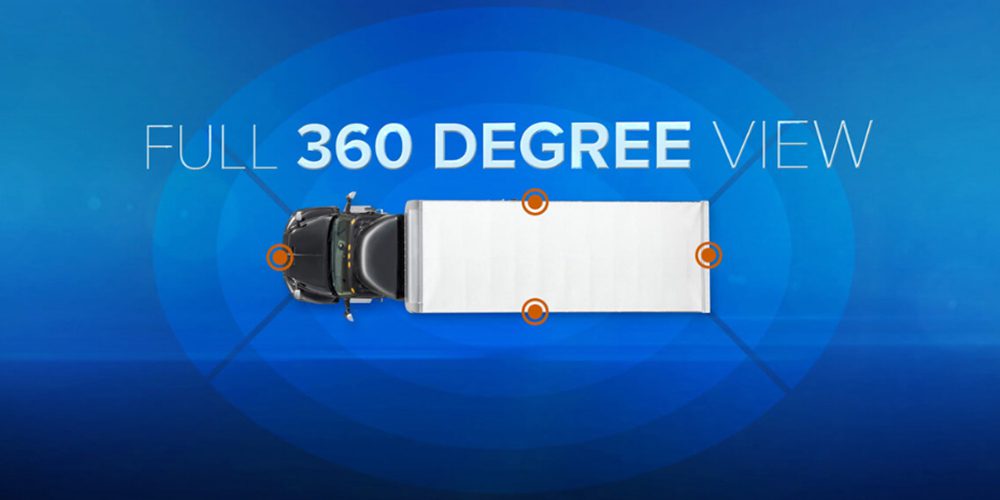

Enhanced Situational Awareness – It’s worth noting that work trucks are where drivers spend their day driving, operating, loading and unloading. Since the pandemic, a changing workforce environment has resulted in labor shortages that place even more stress on drivers. Morgan Truck Body is introducing technologies to streamline and reduce driver information overload. Part of building a better body means focusing on the psychometrics and ergonomics of our designs. We’ve incorporated into our truck body design multiple sensors and vision systems to operate simultaneously and provide information in a user-friendly manner. That includes cameras, sensors and artificial intelligence designed to alert drivers to potential road hazards and distracted driving behavior, 360-degree vision systems that provide both the driver and loading personnel better visibility to the surrounding environment, and interior cargo cameras to detect shifting load conditions.

Image: Morgan Truck Body

Led by COO and President, Mark Hope, EAVX is the innovation center of JB Poindexter & Co. that brings together chassis partners, body builders and technology suppliers for the purpose of integrating the design of next-generation commercial vehicles. This enables EAVX to combine an in-house design studio and strategic partnerships with the power of Morgan Truck Body’s existing manufacturing infrastructure and industry knowledge. The result provides customers and partners with solutions from ideation through commercialization.

As Morgan Truck Body celebrates its 70th Anniversary, the company remains committed to our vision as the industry’s preferred global partner providing innovative middle-mile solutions that connect the world’s supply chain. We’re ready to lead with a collaborative approach and support customers when and where they need us . . . on the road to an electrified future!

Visit Morgan Truck Body and EAVX at ACT Expo 2022 Booth #567, May 9-12.